Ohio Hill Equipment: Master Maintenance Now!

Precision engineering, a cornerstone of Ohio Hill Equipment's operational integrity, is crucial for maximizing uptime and minimizing downtime. The rugged terrain of Appalachia, a significant operational context for many businesses, necessitates diligent maintenance of hill equipment Ohio. Therefore, understanding hydraulic systems, the lifeblood of much heavy machinery, allows for proactive intervention, preventing costly failures. Furthermore, adhering to OEM (Original Equipment Manufacturer) specifications, as recommended by industry leaders like Caterpillar, ensures optimal performance and extends the lifespan of your hill equipment ohio. Effective maintenance strategies are paramount for the success of operators within this challenging environment.

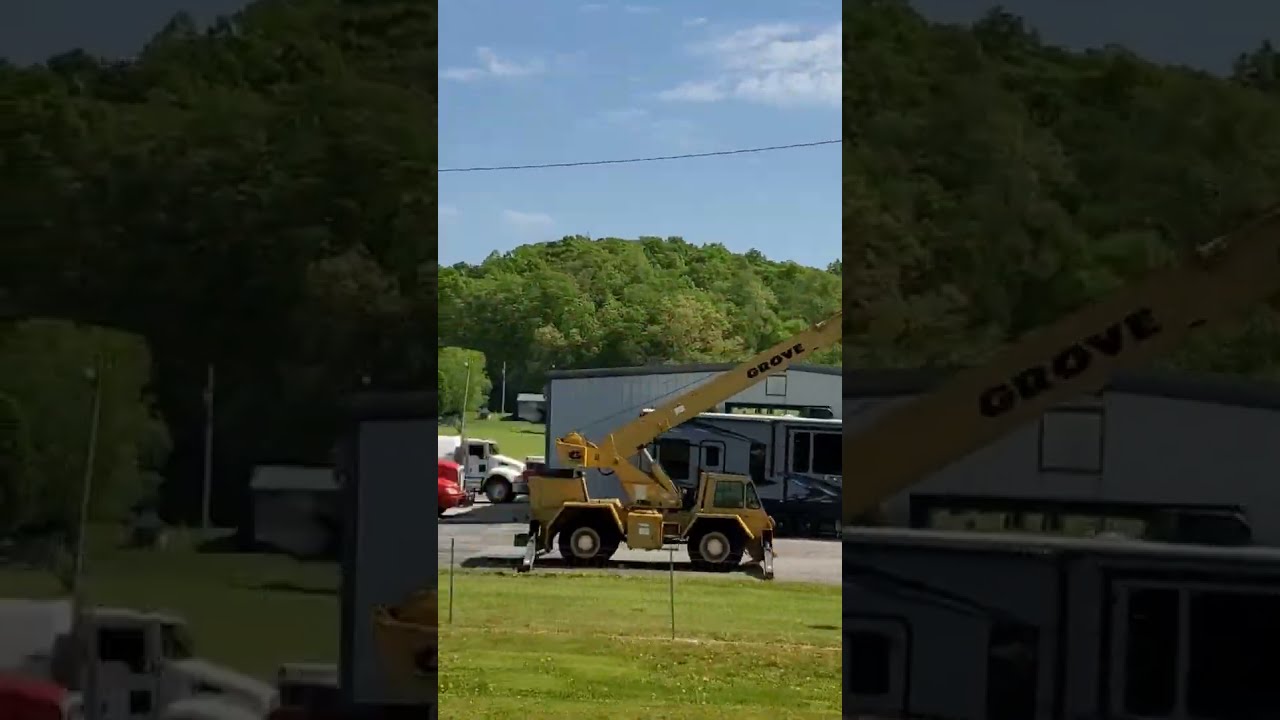

Image taken from the YouTube channel Sweet Talkin' Classic , from the video titled Hills and Hollers of Southern Ohio .

Optimizing Article Layout: "Ohio Hill Equipment: Master Maintenance Now!"

To effectively target the keyword "hill equipment ohio" and deliver valuable information on maintenance practices, the following article layout is recommended. The structure aims to provide a clear, logical progression for the reader, optimizing both user experience and search engine visibility.

I. Introduction: Setting the Stage for Hill Equipment Maintenance

This section should immediately grab the reader's attention and establish the importance of proper maintenance for hill equipment in Ohio.

- Hook: Begin with a compelling statistic or anecdote related to equipment failure in hilly terrain, specifically within Ohio. For example, "Did you know that equipment breakdowns in Ohio's hilly regions cost businesses an average of $X per year?"

- Keyword Introduction: Naturally incorporate "hill equipment ohio" within the first paragraph. For instance, "Maintaining hill equipment in Ohio presents unique challenges due to the demanding terrain and environmental conditions."

- Problem Statement: Clearly state the problems arising from neglecting maintenance – increased downtime, safety risks, and shortened equipment lifespan.

- Solution Overview: Briefly outline the key areas of maintenance that the article will cover. This acts as a roadmap for the reader.

II. Understanding the Challenges of Hill Equipment in Ohio

This section dives into the specific factors that make hill equipment in Ohio require meticulous maintenance.

A. Terrain and Slope Considerations

- Impact of Inclines: Explain how steep slopes increase strain on engines, transmissions, and braking systems.

- Uneven Surfaces: Describe how uneven terrain contributes to wear and tear on tires, suspension, and chassis.

B. Environmental Factors Specific to Ohio

- Weather Extremes: Discuss how Ohio's hot summers, cold winters, and frequent precipitation impact equipment.

- Moisture and Corrosion: Highlight the risks of rust and corrosion due to humidity and road salt.

III. Essential Maintenance Practices for Hill Equipment Ohio

This is the core of the article, providing actionable advice and best practices.

A. Preventative Maintenance Schedules

-

Importance of Regular Inspections: Emphasize the need for routine checks to identify potential issues early.

-

Example Checklist: Provide a sample preventative maintenance checklist, customizable for different types of hill equipment.

- Engine Oil Level

- Coolant Level

- Tire Pressure and Condition

- Brake Functionality

- Hydraulic System Leaks

-

Frequency Recommendations: Suggest maintenance intervals based on usage and environmental conditions. Use a table for clear presentation:

Maintenance Task Frequency Oil Change Every X Hours Filter Replacement Every Y Hours Brake Inspection Every Z Hours Tire Rotation Every A Hours

B. Addressing Specific Equipment Needs

- Engine Maintenance: Focus on optimizing engine performance for uphill climbs and preventing overheating.

- Air filter maintenance

- Cooling system checks

- Transmission and Drivetrain: Explain the importance of proper lubrication and inspection for smooth operation on inclines.

- Gear oil types and change intervals

- Universal joint inspection

- Braking System: Highlight the critical role of brakes on hills and the need for regular maintenance.

- Brake pad/shoe inspection and replacement

- Brake fluid checks and flushing

- Tire Management: Emphasize tire pressure monitoring and tread depth for optimal traction and safety.

- Recommended tire pressures for different terrains

- Tire rotation patterns

C. The Role of Professional Maintenance Services

- Benefits of Expert Technicians: Explain why using qualified technicians can save time and money in the long run.

- Specialized Equipment for Hill Terrain: Discuss the advanced tools and diagnostic equipment that professional services offer.

- Finding Reputable Services in Ohio: Provide tips on how to locate trustworthy hill equipment maintenance providers in Ohio.

IV. Maximizing Equipment Lifespan and Minimizing Downtime

This section focuses on the long-term benefits of consistent maintenance.

A. Reducing Repair Costs

- Early Detection and Prevention: Explain how proactive maintenance reduces the need for costly repairs.

- Extending Equipment Lifespan: Discuss how regular upkeep prolongs the useful life of hill equipment.

B. Enhancing Safety

- Preventing Accidents: Emphasize the role of maintenance in preventing equipment-related accidents on hills.

- Operator Training: Briefly mention the importance of operator training for safe and efficient equipment operation.

C. Improving Efficiency and Productivity

- Optimizing Performance: Explain how well-maintained equipment performs more efficiently.

- Minimizing Downtime: Discuss how regular maintenance reduces unexpected breakdowns and downtime.

Video: Ohio Hill Equipment: Master Maintenance Now!

Ohio Hill Equipment Maintenance FAQs

Here are some common questions regarding the importance of mastering your maintenance routines for Ohio hill equipment. Proper maintenance ensures longevity and optimal performance.

Why is maintenance so crucial for equipment used in hilly Ohio terrain?

Equipment operating on Ohio's hills faces increased stress due to inclines and varied terrain. Regular maintenance, including lubrication and inspection of wear points, helps prevent premature breakdowns and costly repairs specifically related to that stress and strain on hill equipment in Ohio.

What are some quick daily maintenance tasks I should prioritize?

Before each use, check fluid levels (oil, coolant, hydraulic), inspect tires for proper inflation and damage, and ensure all safety devices are functioning correctly. Clean off any excess debris or mud, especially in the engine and undercarriage. Doing this regularly for your Ohio hill equipment will make your life easier.

How often should I schedule a professional maintenance service?

The frequency depends on the equipment type and usage. However, a general guideline is to schedule a professional service at least every 200-250 hours of operation or annually, whichever comes first. Ohio hill equipment often needs this service more frequently due to the work load.

What happens if I neglect proper maintenance on my Ohio hill equipment?

Neglecting maintenance can lead to significant problems, including reduced performance, increased fuel consumption, higher repair costs, and potential safety hazards. Over time, the lack of proper care drastically shortens the lifespan of your hill equipment ohio.

Alright, folks, that's the gist of keeping your hill equipment Ohio in tip-top shape! Remember, a little maintenance goes a long way. Now go out there and get the job done!